Pharma

Home / Pharma

BFS ASEPTIC FILLING EQUIPMENT

End usage of the bottle or an ampoule evaluates the additional functions used to fill the container. Micro Tool machines can manufacture canisters, bottles, ampoules, drop bottles, bellows containers, and portion packaging in a variety of forms and plastic blends, with filling volumes ranging from 0.01 ml to 3,000 ml, aseptically or traditionally – fully automatic and without human intervention in all cases.

PHARMACEUTICAL PACKAGING SOLUTIONS

-

Eye, ear, and nose drops

-

Homeopathics

-

Inhalation solutions

-

Infusions and injections

-

Rinsing solutions

-

Drinkable solutions

-

Creams, ointments, and gels

-

Wound care products

-

Vaginal applications

-

Rectal applications

-

Disinfectants

-

Diagnostic agents

-

Various biotechnological products

-

Oral applications

-

Ointments

-

Stability test kits

-

Sterile water

-

Temperature-sensitive products

-

for the biotech industry such as vaccines,antibodies, and blood products

-

Wound gel

-

Wound irrigation products

-

And much more besides

ASEPTIC FILLING IN HEAT-SENSITIVE APPLICATIONS:

The standard procedure is to fill products at room temperature. But in the pharmaceutical sector in particular, the products being filled can sometimes be highly temperature sensitive. Micro Tool therefore developed for such instances. This involves special measures that maintain the product at a stipulated temperature before it is filled and that cool the newly moulded plastic containers quickly. High processing speed is guaranteed and the product being filled is subject to maximum protection at all times justifying the BFS technology.

SINGLE OR MUTLILAYER PHARMACEUTICAL PACKAGING:

A single layer of polyethylene or polypropylene is usually more than adequate to contain the product safely and in accordance with its usage. But sometimes one layer simply isn’t enough, for example when the packaging solution has to perform other functions, too, in particular such as increasing the steam or gas barrier. In this and many similar cases, special machines can be used to manufacture multilayer plastic packaging. This packaging is made of multiple layers that have accurately the correct features to offer the product utmost protection. No matter what your product needs, Micro Tool machines can manufacture the solution.

SEALING OR DOSING:

Eye drops, inhalation products, products for rectal or vaginal application, and ointments, creams, or gels – all BFS containers can be made ready to use and with the designated product and applications.

UNIT-DOSE OR MULTIDOSE CONTAINERS:

Irrespective of your product is designed for single or multiple uses, our machines can mould the containers accordingly, accurately fill them, and add closing mechanisms in accordance with the requirements.

LUER LOCK CONNECTIONS:

When syringes are used, the ampoule design guarantees straight forward and reliable Luer fit or Luer lock connections. The liquid can be drawn up into the syringe simply, safely, and without the need for an additional needle. In the case of air-operated Luer connections, the pressure is equalized automatically. This is pretty neat and is just one of countless ways in which BFS technology offers veritable efficiency.

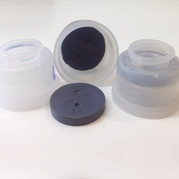

ASEPTIC CONTAINER CLOSURE TECHNQIUES

The right closure for you very much depends on the application and on whether the product is in a unit-dose or multi dose container. What they all have in common is that each and every container is hermetically sealed, resulting in a closure that suits the function – and that’s clean and inexpensive, and functions reliably. The twist-off cap is a closure design which has proven its worth millions of times and which is used in a large number of production areas.

TWIST-OFF CAP:

The twist-off cap is a closure design which has proven its worth millions of times and which is used in a large.

KME:

The KME closure is complemented by a screw cap with a pin. Screwing the pin in creates an opening via which the product can be dripped or squeezed out.

KMT:

The KMT closure consists of two parts and allows the user to accurately dispense drops of the product.

EUROHEAD CLOSURE:

With the euro head closure, the hermetically sealed container is combined with the euro head cap. It was specifically designed to meet the requirements of infusion bottles (IV bottles).

COMMON PHARMACEUTICAL APPLICATIONS

PACKAGING OPHTHALMICs/ EYE DROPS SOLUTIONS WITH BLOW-FILL-SEAL

From single-dose droppers, to multi-dose containers, to large bottles of contact lens solution, blow-fill-seal is a uniquely advantageous method for the aseptic packaging of eye drops and related products.Not only do machines offer cost-effective eye drop production under highly sterile conditions, this method of aseptic filling and packaging also enables flexible container design, a reduced environmental footprint, and preservative-free formulas.

SINGLE-USE DROPPER AMPOULES:

Because single-use (also known as unit-dose) eye drop containers eliminate the threat of cross contamination that emerges from reuse, they have long been the preferred packaging for preservative-free eye drops. BFS eye drop ampoules created with are made from environmentally friendly LDPE, a low-impact and light weight material. In addition to being produced in a self-contained system, the resulting eye drop containers are easy to recycle

KEY FEATURES AND BENEFITS

-

Filling volumes up to 0.5 ml

-

Easy handling and precise dosing

-

No cross contamination

-

Lightweight, low-impact LDPE

PACKAGING INHALANTS/ NEBULIZER SOLUTION WITH BLOW-FILL-SEAL:

In the production and packaging of nebulizer solutions and other inhalant medications, BFS processing offers a safer, more user-friendly, and more cost effective alternative to glass ampoules.

Key features and benefits for inhalants:

-

Precise dosing in single-use containers

-

Filling volumes between 1ml- 5ml

-

Made from mono material LDPE or PP resins

-

Highest sterility assurance

-

Distinctive, user-friendly container designs

ENHANCED STERILITY AND SAFETY

-

Plastic ampoules created in a blow-fill-seal process eliminate the risks associated with glass containers, such as lacerations, splinters, and trace particulate contamination upon opening. These characteristics make blow-fill-seal packaging ideal for nebulizer and other inhalant solutions used in critical care applications.

-

Furthermore, as a highly hygienic packaging and filling process requiring minimal human intervention, blow-fill-seal has been verified to produce pharmaceutical packaging that is virtually free of endotoxins and viable microorganisms.

EASY TO USE FINAL PRODUCT

BFS ampoules offer a convenient container and closure system for the treatment of chronic pulmonary diseases, both by healthcare professionals and the patients themselves. Especially compared to glass, light weight BFS packaging makes inhalant solutions easy to transport, store, and dispense, with no risk of shattering.

COST-EFFECTIVE, CUSTOMIZED PRODUCTION

The flexibility of blow molding allows for endless possibilities in container design. Nebulizer solutions and respiratory care products packaged on machines can be easily customized to include distinctive designs and tamper evident closures. Blow-fill-seal eliminates the need for costly container inventory, storage, and sterilization operations by carrying out container forming, filling, and closure in a single continuous process.

PACKAGING INJECTABLES AND INTRAVENOUS SOLUTIONS:

As a completely closed system that eliminates the need for pre-formed containers and films, simplifies the filling and From small plastic vials to IV containers, blow-fill-seal offers the ideal combination of hygiene, user-friendliness, and cost-effectiveness for aseptic packaging of parenteral solutions. BFS technology enables the creation of customized plastic containers designed for especially easy storage, inspection, packaging of sterile injectables and intravenous fluids

SMALL VOLUME CONTAINERS FOR STERILE INJECTABLES:

Major advances in blow-fill-seal technology have made plastic ampoules into an asset for parenteral manufacturing facilities and health care professionals. Compared to glass vials with rubber stoppers, ampoules that are formed and filled on machines are at lower risk of both breakage and contamination. Furthermore, the blow-fill-seal technique allows for the creation of innovative packaging for easy administration. Sterile injectables filled via blow-fill-seal can be withdrawn without needles and directly connected to luer syringes.

Key features and benefits

-

Filling volumes between 1 ml - 30 ml

-

Plastic resins: mono material LDPE or PP

-

Option for terminal sterilization

-

Low absorption and moisture permeation

-

Safely disposable and easily recycled

LARGE VOLUME IV CONTAINERS :

IV solutions are basic life-saving drugs that are as wide ranging as their applications, including hydration agents, chemotherapy, pain management, antibiotics, plasma volume expanders, total parenteral nutrition, and many more. The blow-fill-seal process offers the highest level of sterility assurance in this field of pharmaceutical manufacturing matched with low production costs. The resulting IV containers are translucent, light weight, and shatter proof for optimal accessibility.

Key features and benefits:

-

Filling volumes between 100ml - 3000 ml

-

Inert, drug compatible raw materials

-

Flexible material for non-vented IV tubing

-

Good fill volume for admixture preparations

-

Batch and expiry information displayed permanently in container

-

No contact between cap and IV solution

-

Self-standing and non-slip container

PACKAGING VACCINES:

Bringing new vaccines to market invariably involves extensive research and trials, but also a number of manufacturing challenges. For one thing, vaccines may be highly sensitive to temperature, primary packaging materials, and agitation. Furthermore, the often small batch sizes can prove challenging in scaling the production of injectables in order to fulfill urgent and widespread needs for new vaccines.

The ideal filling equipment for highly potent and sensitive liquids, blow-fill-seal technology, offers an innovative solution to many challenges of the vaccine manufacturing process. This continuous aseptic packaging technique combines high production efficiency with the utmost sterility to produce vaccine containers that are quick to distribute and easy to administer.

Single-use vaccine containers made via blow-fill-seal are manufactured to contain the precise dosage to be administered. In this way, human error that may lead to the over- or under dosing of vaccines is virtually eliminated.

Key features and benefits for vaccine filling and packaging:

-

Flexible fill volumes from 0.1 ml

-

Made from mono material LDPE resins

-

Sterile dosage form

-

Highest sterility assurance

-

Highly automated process minimizes risks for people and the environment

-

BFS technology for temperature sensitive products

-

Single-use containers prevent tampering and incorrect dosing

-

Customized container designs for differentiated product applications

-

Ideal for products that must be stored at low temperatures

-

Flexible application possibilities, from micro batches to clinical studies to market launches

FILLING HEAT-SENSITIVE BIOLOGICALS INCLUDING VACCINES:

While standard BFS aseptic filling processes are performed at room temperature, MicroTools BFS technology for machines protects the potency of heat-sensitive ingredients used to manufacture vaccines. The BFS system keeps the product at a pre designated temperature and uses special mechanisms to quickly cool the newly moulded vaccine containers before filling.